WelPacker DAC Advantages:

- Hydraulic pressure station protects the packing material and reduces percussion for the ground.

- Simple pipe layout brings bigger operating space and added convenience.

- Pneumatic and electric power sources optional reduce the noices and extra cost of gas cylinders.

- Short packing time avoids bad column efficiency.

- Piston head keeping contact with column bed avoids bed collapse and poor lifetime.

- No electrical parts apply to anti-explosion area.

- Unique fluid/sample distribution ensures high column efficiency.

WelcPacker DAC column complies with the relevant regulations below:

- ICH Good Manufacturing Practice Guidelines (GMP) for APIs

- Environmental Health Safety (EHS)

- ISPE's Pharmaceutical Engineering Design Guidelines

- GAMP Good Automated Manufacturing Practice

- International Electrotechnical Commission Certification System for Explosion-proof Electrical Products

- American Society for Testing and Materials Standards (ASTM)

- Chinese Drug Administration Law

- ChP Chinese Pharmacopoeia (2020 Edition)

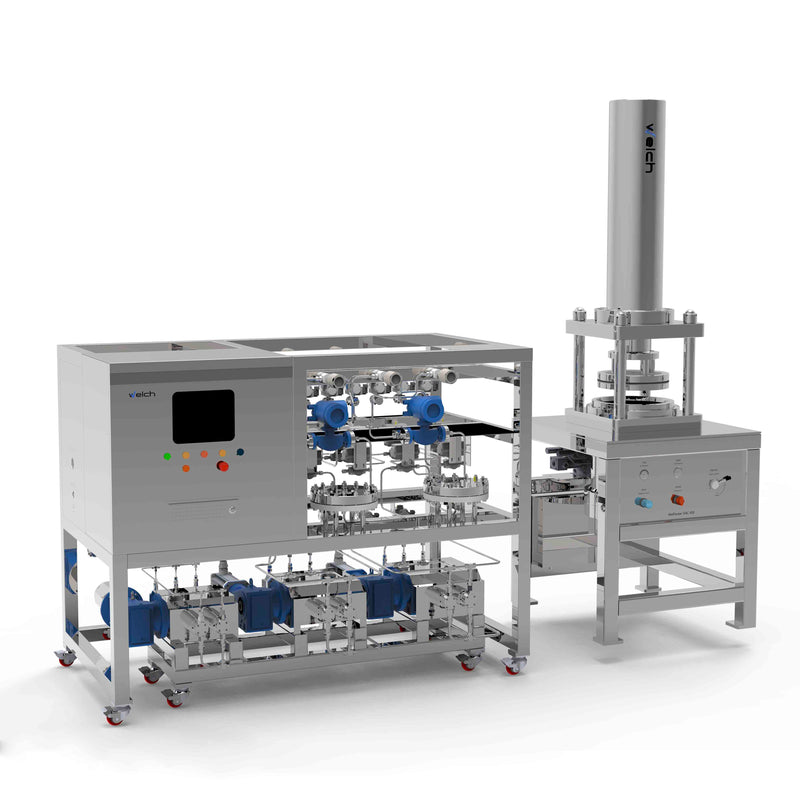

The system is divided into a DAC column, liquid circuit control and fraction collection system, detection and electrical control system, etc.

Other Components Introduction

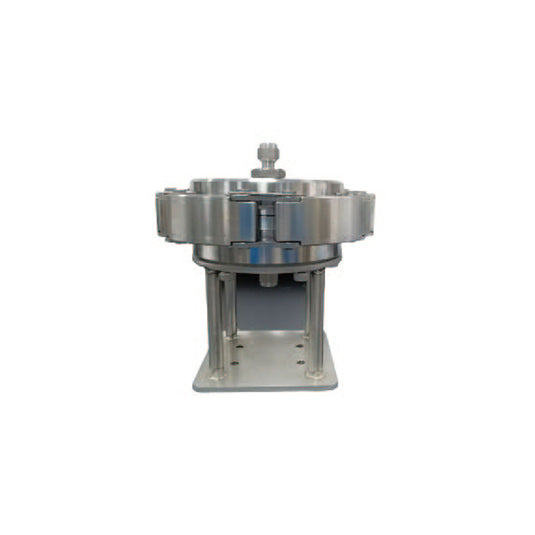

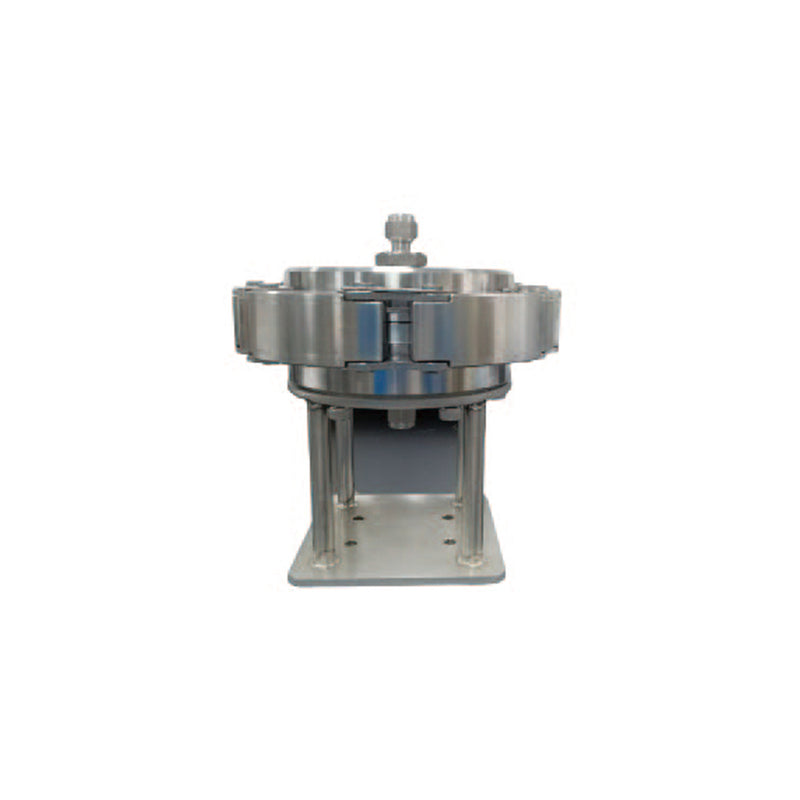

High-pressure sealing ring

Column tube

Distributor

Hydraulic station

Pison turnover support

Preparative online filter

The preparative inline filter consists mainly of a frit, sealing ring, and clamp. When the liquid passes through the inline filter, particles larger than the pore size of the frit are retained, ensuring that the outgoing liquid is free from large particles and preventing them from entering the chromatographic column and detector. This helps prevent clogging of the preparative column caused by large particles, thereby extending the lifespan of the preparative column. Additionally, it also helps reduce wear and tear on the sealing components.

Homogenization system

The homogenization system consists of a homogenization tank and related equipment, which is used to facilitate the packing of chromatography columns and complete the homogenization process of the packing material before packing. During homogenization, the packing material medium for packing the chromatography column is thoroughly mixed with the packing solvent in the homogenization tank by the motor-driven stirring paddle. It is then rapidly transported into the column tube, effectively avoiding the hazards of dust and volatile solvents, and ensuring the health and safety of laboratory personnel.

The homogenization tank provides functions for homogenization stirring, homogenization circulation, and delivery of homogenization liquid. It can be customized in different volumes to meet the filling requirements of various specifications of chromatography columns.

WelPacker DAC Advantages:

- Hydraulic pressure station protects the packing material and reduces percussion for the ground.

- Simple pipe layout brings bigger operating space and added convenience.

- Pneumatic and electric power sources optional reduce the noices and extra cost of gas cylinders.

- Short packing time avoids bad column efficiency.

- Piston head keeping contact with column bed avoids bed collapse and poor lifetime.

- No electrical parts apply to anti-explosion area.

- Unique fluid/sample distribution ensures high column efficiency.

WelcPacker DAC column complies with the relevant regulations below:

- ICH Good Manufacturing Practice Guidelines (GMP) for APIs

- Environmental Health Safety (EHS)

- ISPE's Pharmaceutical Engineering Design Guidelines

- GAMP Good Automated Manufacturing Practice

- International Electrotechnical Commission Certification System for Explosion-proof Electrical Products

- American Society for Testing and Materials Standards (ASTM)

- Chinese Drug Administration Law

- ChP Chinese Pharmacopoeia (2020 Edition)

The system is divided into a DAC column, liquid circuit control and fraction collection system, detection and electrical control system, etc.

Other Components Introduction

High-pressure sealing ring

Column tube

Distributor

Hydraulic station

Pison turnover support

Preparative online filter

The preparative inline filter consists mainly of a frit, sealing ring, and clamp. When the liquid passes through the inline filter, particles larger than the pore size of the frit are retained, ensuring that the outgoing liquid is free from large particles and preventing them from entering the chromatographic column and detector. This helps prevent clogging of the preparative column caused by large particles, thereby extending the lifespan of the preparative column. Additionally, it also helps reduce wear and tear on the sealing components.

Homogenization system

The homogenization system consists of a homogenization tank and related equipment, which is used to facilitate the packing of chromatography columns and complete the homogenization process of the packing material before packing. During homogenization, the packing material medium for packing the chromatography column is thoroughly mixed with the packing solvent in the homogenization tank by the motor-driven stirring paddle. It is then rapidly transported into the column tube, effectively avoiding the hazards of dust and volatile solvents, and ensuring the health and safety of laboratory personnel.

The homogenization tank provides functions for homogenization stirring, homogenization circulation, and delivery of homogenization liquid. It can be customized in different volumes to meet the filling requirements of various specifications of chromatography columns.

Contact Us

Please fill out the form below and we’ll get back to you within 24 hours.